OpenFoam - radial swirler burner

OpenFoam - radial swirler burner

Overview:

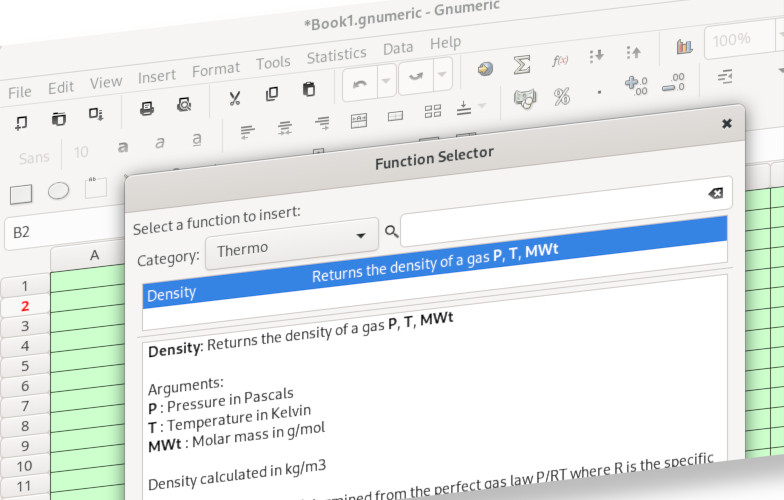

Complex parametric models can be created that are easily imported into OpenFOAM

Introduction

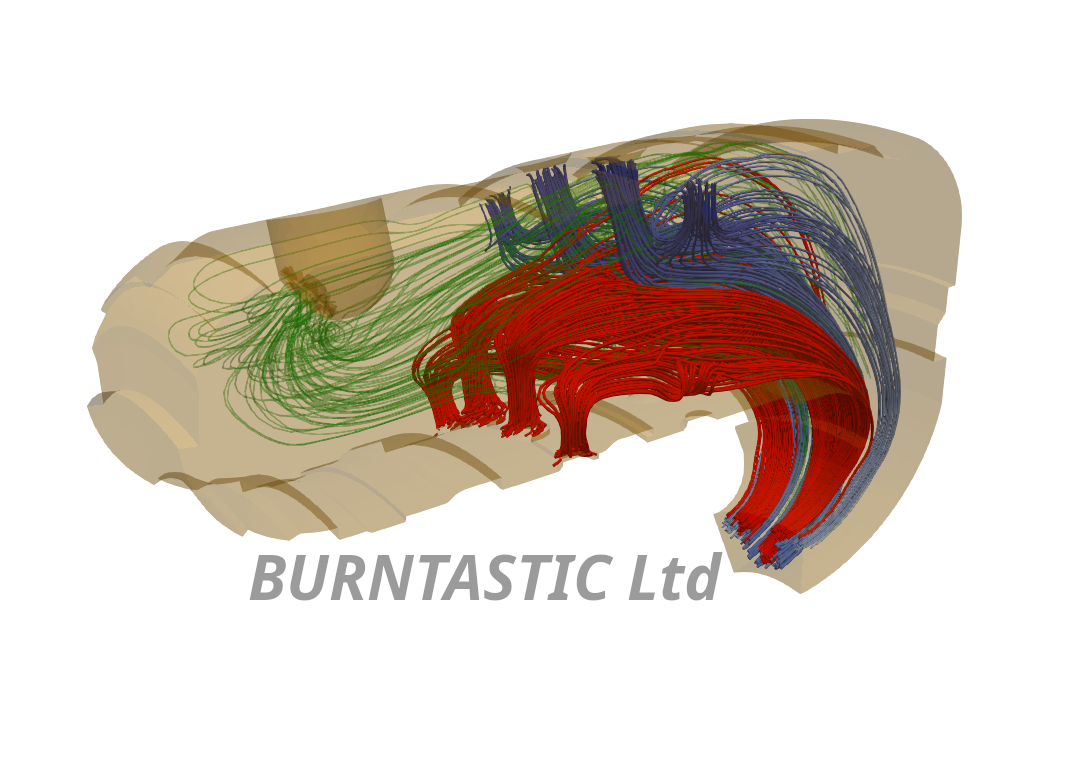

This is a generic radial swirler burner designed to work on industrial gas turbines for power generation. The geometry is not specific to any particular burner.

The model was created in Salome software. The model is defined in a python script in which all the key geometric parameters are defined. It is therefore possible to use this in a fully parametric analysis of the geometry, so that flow filed changes can be linked directly to geometry modifications.

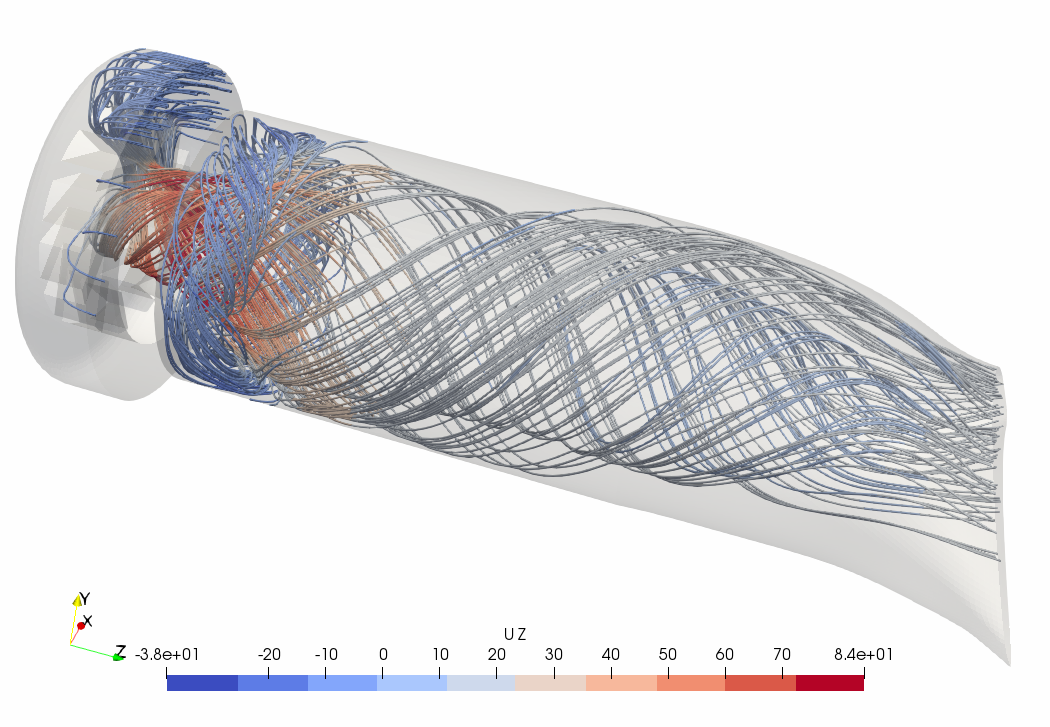

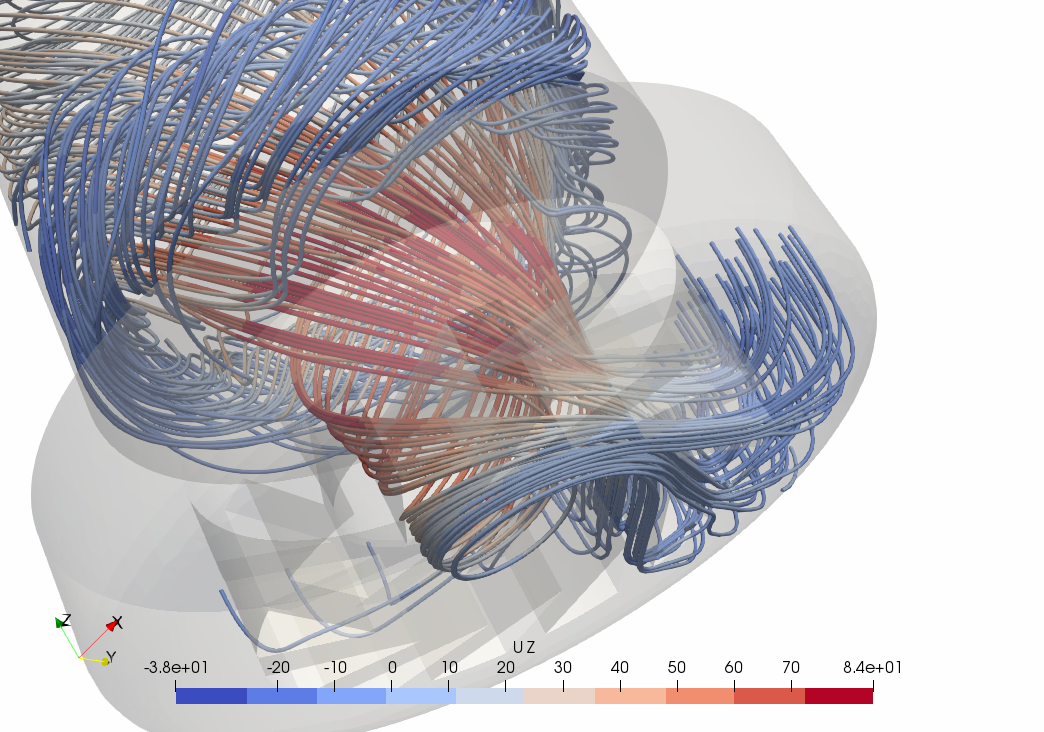

The transition duct section of the geometry is defined using around 10 key parameters allowing for various types of duct to be studied for internal and external aerodynamic flows.

Where these models can be used

The model shown is an isothermal flow case and can provide initial concept design data for the selection of design candidates for either further detailed analysis or hardware build.

This particular geometry is generic and doesn’t include fuel injection ports.

The streamlines show the flow through the swirl slots and out into the combustor. The central vortex is clearly visible.

The model uses an unstructured grid based on the salome implementation of Netgen. In this 3D model the Netgen boundary layer function is implemented on the slot, prechamber and combustor walls.

Python code implimentation

Briefly, the python script must contain the following header section.

1import os

2import math

3

4import sys

5import salome

6

7salome.salome_init()

8import salome_notebook

9notebook = salome_notebook.NoteBook()

10sys.path.insert(0, r'/home/nigel')

11

12###

13### GEOM component

14###

15

16import GEOM

17from salome.geom import geomBuilder

18import math

19import SALOMEDS

20

21geompy = geomBuilder.New()The parameters defining the transition duct are contained in the python script and are shown below

1# duct parameters

2

3comb_diameter = 250.0 # Combustor diameter (mm)

4duct_number = 8 # Number of ducts

5NGV_tip_radius = 420 # NGV tip radius (mm)

6NGV_root_radius = 350 # NGV root radius (mm)

7comb_cant_angle = 35 # Combustor cant angle (deg)

8duct_axial_length = 280 # Duct axial length (mm)

9Influence_a = 0.22 # Influence factor Fa - cord centre line

10Influence_b = 0.52 # Influence factor Fb - cord centre line

11NGVin_Angle = 0 # NGV Inlet angle NGVin_Angle

12comb_in_Angle = 0 # Combustor Inlet angle comb_in_Angle (keep at 0 most times!!)

13cord_inter = 10 # Intervals/descretisation on cord line

14Na = 5.2 # Bottom Control Na

15Nb = 3.1 # Top Control Nb (more nozzle like as -> 0)

16corner_control = 5 # Corner Control Nc

17corner_max = 5 # Maximum Corner Cmax change this to make the exit square or not

18corner_min = 2 # Minimum Corner Cmin

19ellipse_discret = 20 # ellipse discretisationWhen the model and meshing is completed, boundary faces need to be defined to enable better import into openFOAM. A script file is used to enable adjustment of these boundary patches prior to the OpenFOAM run.

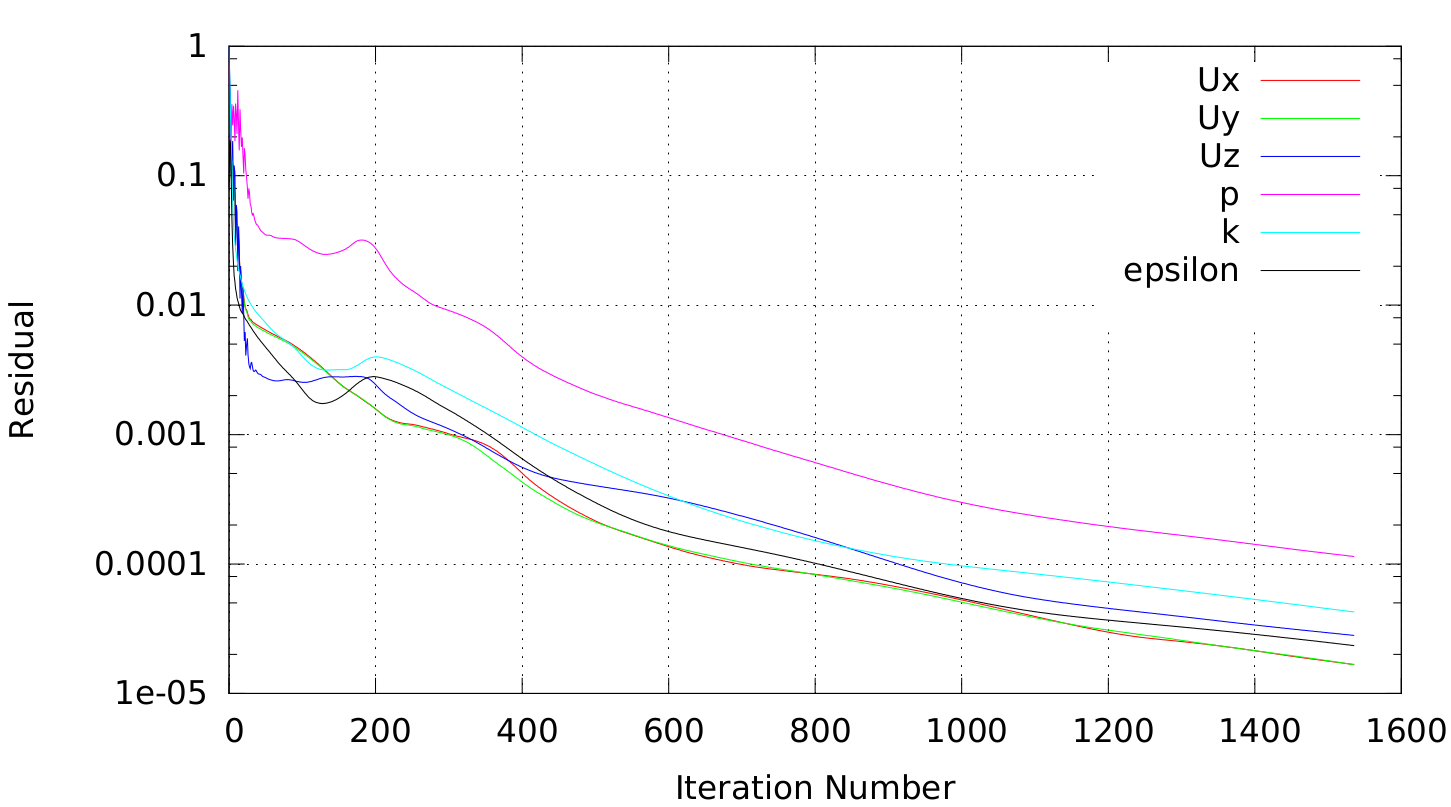

Calculations for highly swirling flows generally require a Reynolds stress turbulence model to correctly capture the flow field. Prior to activating the Reynolds stress model the simpler k-epsilon model is used and the convergence history for that is shown below.

Conclusion

The modelling of a representative gas turbine combustion system using open source tools has been demonstrated. The use of an unstructured mesh is used here but a structured mesh is possible using openFOAM’s snappy hex mesher based on the CAD export from salome.

While the use of such simplified mesh and modelling has its limitations, the use of open source code and the ability for parametric studies opens the door for optimization analysis at affordable economic levels. This then allows small companies top offer this analysis service while at the same time making possible scaling of the optimization to include as many design and operational parameters as the client may need.